Fuselage 1

Fuselage page 1

I got the design for my two worktables from an EAA (Experimental Aircraft Association) chapter website. One table is 4' by 8', the other is 3' by 4'. (For basic plans, click here).

Here I'm taking inventory of all my newly-delivered wood. The skeleton of the plane is made of Sitka spruce, which has long been used for aircraft construction because of its strength and lightness. All the wood has to be aircraft-grade quality. It's expensive stuff. In addition to spruce, you use a lot of aircraft-grade plywood. I used 3/32" thick mahogany ply for the sides of my aircraft and birch ply for the bottom. Birch is stronger but a little heavier.

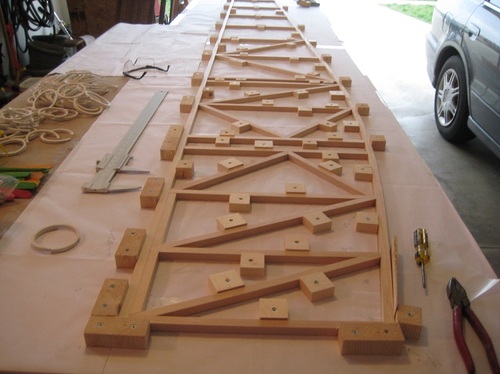

You start by making two identical side panels.

Now I'm inserting the vertical and diagonal pieces.

Many gussets--small triangular wooden pieces--are inserted into all the corners for strength. I used T-88 two-part epoxy for all my structural gluing. It's tremendously strong stuff. I used a scale to mix it in the proper proportions (to the tenth of a gram). The white rings are clamps I made out of 4" PVC pipe. You can make hundreds of versatile clamps for about ten dollars.

Above, I'm getting a little ahead of myself.